The SATO Company is the leading contributor of the data collection technology and auto identification solutions or Sato name tags for the physical care sector, partner’s suppliers to deliver streamlined, labeling solutions and tailored print, using barcode and RFID technology, that will enable real-time obviousness of the hospital case to able the managers in optimizing the decision making, together with the bottom line.

Through the aging people in lots of mature economies, the health care costs had been dramatically rising from around the world. Furthermore, every healthcare organization needs to maintain the vast diversity of medical supplies that will meet the broad requirements of the patients that places heavy demands with the inventory control.

The healthcare authorities and the government alike are looking for ways to lessen the costs, optimize the effectiveness through careful assessments of the processes, products, and the people in the organizations and to drive down the waste.

The prevention of waste and the optimization of inventory in the pharmaceutical supply and in the medical chain is now the key to cash flow and hospital budget management. Whether privately-owned hospitals and organizations or state hospitals, the pressure on the budgets is bigger than ever before and the managers are looking for ways to decrease the costs, while it continue to operate efficiently and manage the patient’s care and safety.

Having the capability to precisely trace and track medicines, medical devices, hospital and equipment assets, real time 24/day, give greater insight into the medical inventory and helps in driving efficiency, and also decreases the mistakes.

WITH BARCODES

This SATO Company is the leader in the auto identification and also the data collection solutions of the healthcare sectors comprehends the significance of having accurate, reliable and updated information for permitting managers to make efficient, manage their budgets and with timely decisions. From the health care provider perspective, the accurate patient data and closely tracking of medical supplies are critical factors in giving the perfect care to the appropriate patient.

The healthcare sector effectiveness is improved through the rapid barcodes adoption; making it easy to manage and track the patient information and the medical supplies, in 24 hours/day, with the actual-time information eliminating medical mistakes and enhancing patient safety. Through the massive array of barcode-based information collection systems accessible to medical institutions that will track the products, inventory and assets efficiently. SATO develops and styles customized data gathering solutions to aid in handling the supply chain effectively; keep inventories lower and protect the patient safety.

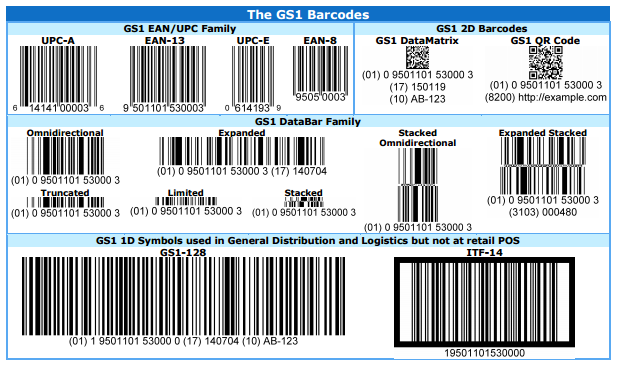

The guidelines for applying the standard barcodes on the clinical devices able sophisticated and efficient distribution systems, effective medical administration with traceability, and also eradicates medical errors. The use of GS1 conforming barcodes on the medical devices able inventory decreases as well as improving patient safety.

The management in procurement and medical devices is usually manual and expensive in time application, with the inherent dangers in mistakes leading to stock out, obsolete or fraud products. By implementing the digital inventory management systems, using the GS1 compliant barcode, the medical or hospital facility can rapidly automate and register worldwide trade lot numbers, item numbers, and expiration dates, allowing the staffs to trace and track safely medical devices from across the network. The data developed will help staffs in handling orders in which products are used, automatically jot down products and also reorder products from the suppliers. Furthermore, in automating the clinical device management procedure, the system assures employees that the products needed for every day’s work were in stock, thereby decreasing the danger of postponing procedures or appointments and improving patient safety.

Related post: